EU GMP Annex 1: What It Means for Pharmaceutical Quality and Safety

When it comes to making medicines that are safe to inject or use in hospitals, EU GMP Annex 1, the European Union’s strict set of rules for sterile pharmaceutical manufacturing. It’s the baseline every drug maker must hit to sell injectables, eye drops, or IV solutions in Europe—and many global companies follow it even if they’re not based there. This isn’t just paperwork. It’s about stopping bacteria, viruses, and tiny particles from getting into your medicine before it reaches a patient’s bloodstream. One mistake can mean a hospital outbreak, a recall, or worse.

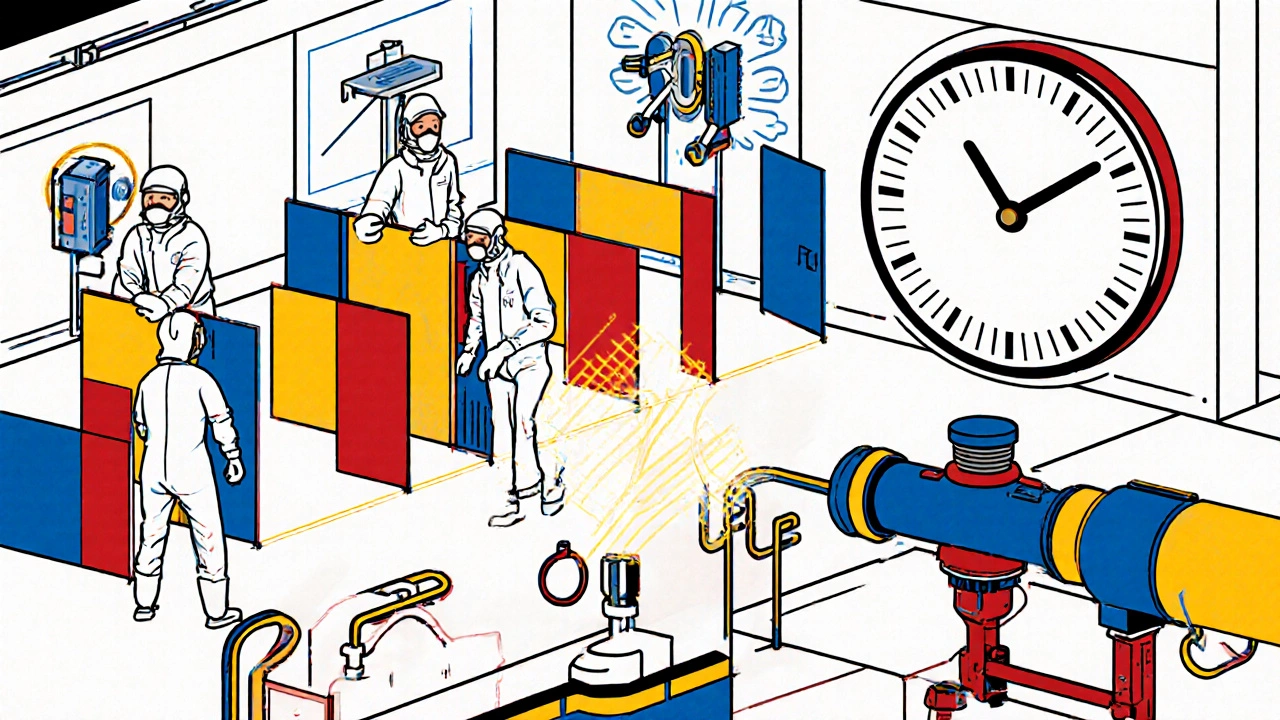

It’s not just about clean rooms and filters. GMP compliance, the broader system of good manufacturing practices that EU GMP Annex 1 builds on requires constant monitoring, staff training, and proof that every step is controlled. If you’re making a sterile product, you can’t just hope it’s clean—you have to prove it. That means air sampling, surface swabs, and real-time particle counters. sterile products, medicines designed to be free of all living organisms, like vaccines or chemotherapy drugs are under the heaviest scrutiny because there’s no room for error. A single contaminated vial can kill someone.

EU GMP Annex 1 also forces companies to think ahead. It’s not enough to fix problems after they happen. You need to predict them. That’s why it pushes for risk-based approaches, automated systems, and validated cleaning methods. It’s why you’ll see more single-use equipment, isolators instead of open benches, and staff wearing full sterile suits. It’s why every batch has to be tracked from raw material to patient. This is the reason some small labs can’t make sterile drugs—they can’t afford the infrastructure.

What you’ll find in the posts below are real examples of how these rules play out in practice. You’ll see how contamination risks show up in production, how companies adapt when standards change, and why some generic drugs get pulled while others don’t. There’s no fluff here—just how the system works on the ground. Whether you work in pharma, are curious about drug safety, or just want to know why your IV bag looks so different from your pill bottle, this collection gives you the facts without the jargon.

Understand the latest GMP standards for pharmaceutical and medical device manufacturing in 2025. Learn FDA and EU requirements, key compliance areas, costs, and real-world challenges.