CGMP Requirements: What You Need to Know About Drug Manufacturing Standards

When you take a pill, you expect it to work the same way every time—that’s where CGMP requirements, Current Good Manufacturing Practices that set the baseline for how drugs are made, tested, and documented. Also known as good manufacturing practices, these rules are the backbone of every medicine you buy, whether it’s generic or brand-name. The FDA doesn’t just approve drugs—they check how they’re made. If a factory skips a step, uses dirty equipment, or doesn’t track batches properly, even the best formula can become dangerous.

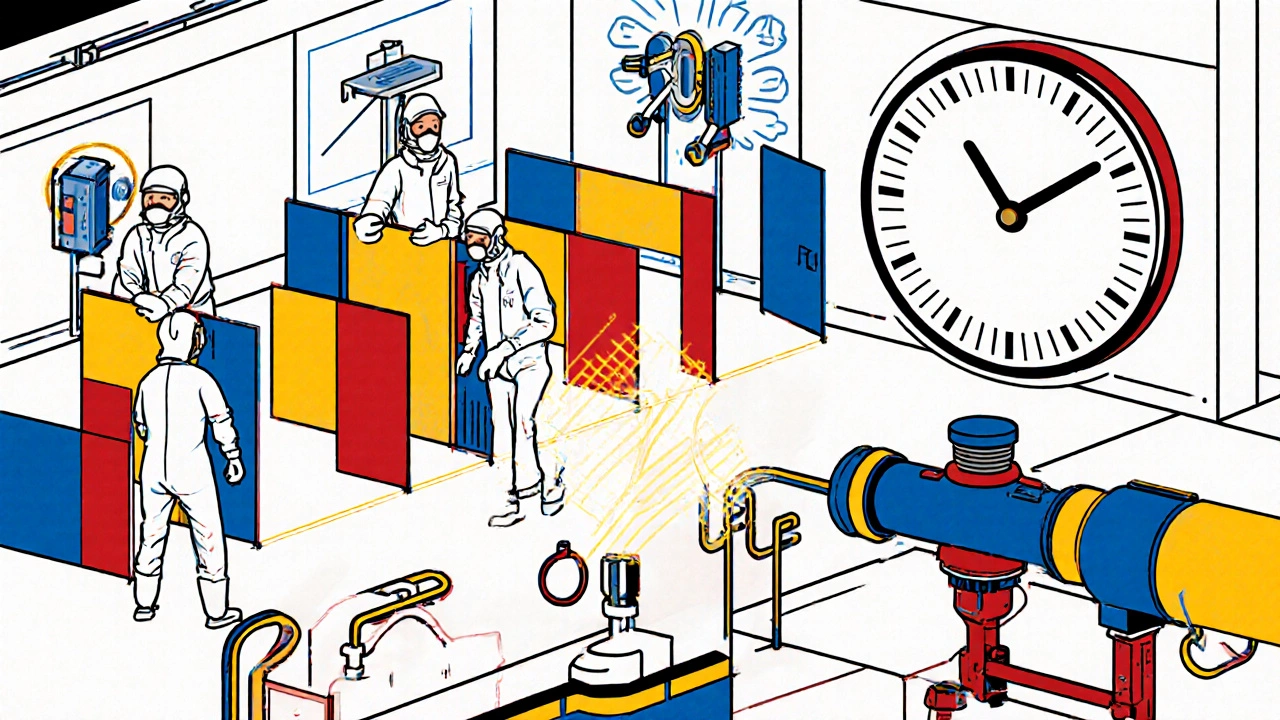

CGMP requirements cover everything from the cleanliness of the floor to the training of the person filling the capsules. It’s not about fancy labs or expensive machines—it’s about consistency. Did the machine that stamped the tablet run at the right speed? Was the raw material tested before use? Was the batch recorded correctly? These aren’t paperwork busywork; they’re the only thing standing between you and a pill that doesn’t work—or worse, harms you. FDA regulations, the legal framework that enforces CGMP rules across U.S. drug manufacturers don’t allow guesswork. Every step must be written down, reviewed, and repeatable. That’s why some companies get shut down: they cut corners, and the FDA catches them.

These rules don’t just protect patients—they protect the system. If one batch of a common antibiotic is contaminated, it can cause outbreaks. If a heart medication doesn’t dissolve properly because of poor mixing, people could have heart attacks. That’s why pharmaceutical quality, the measurable standard of safety, purity, and effectiveness in every dose is non-negotiable. Even small deviations in humidity, temperature, or mixing time can change how a drug behaves in your body. That’s why manufacturers use automated systems, sensors, and strict batch logs—because humans make mistakes, and CGMP requirements are designed to catch them before they reach you.

You won’t see CGMP requirements on the bottle, but you rely on them every time you swallow a pill. The same rules apply whether you’re taking a cheap generic or a name-brand drug. That’s the point—they level the playing field. If a company can’t meet them, they can’t sell. And if they try to hide violations, the FDA steps in. These aren’t suggestions. They’re the law. And they’re why you can trust that the medicine you buy today will work just like the one you bought last month.

Below, you’ll find real-world examples of how these standards affect the drugs you use—from checking generic equivalence to spotting dangerous interactions. These aren’t abstract rules. They’re the quiet guardrails keeping your medicine safe.

Understand the latest GMP standards for pharmaceutical and medical device manufacturing in 2025. Learn FDA and EU requirements, key compliance areas, costs, and real-world challenges.