When a pharmaceutical company makes even a small tweak to how it produces a drug-like swapping out a mixer, moving a filling line to a different room, or changing the supplier of an ingredient-it’s not just an internal operational decision. It’s a regulatory event. Under U.S. law, manufacturing changes must be classified, documented, and submitted to the FDA before the product can be shipped under the new conditions. Failure to follow the rules can lead to warning letters, product recalls, or even a shutdown of production lines. This isn’t about bureaucracy. It’s about ensuring that every pill, injection, or inhaler you take is safe, effective, and consistent with what was originally approved.

Why Manufacturing Changes Matter

Think of a drug product like a recipe. If you change one ingredient, the taste might be off. If you change the oven temperature, the texture could be ruined. In pharmaceutical manufacturing, even tiny changes can affect the identity, strength, quality, purity, or potency of a medicine. That’s why regulators require strict controls. The FDA’s rules, written under 21 CFR 314.70 for drugs and 21 CFR 601.12 for biologics, exist to prevent accidental harm. A change that seems minor to a production team-like replacing a pump with one from the same manufacturer-could alter how quickly a drug dissolves in the body. That’s not just a technical detail. It’s a patient safety issue.The system isn’t perfect. Companies often struggle to decide whether a change is major, moderate, or minor. One mistake in classification can trigger an FDA inspection. In 2023 alone, the FDA issued four warning letters specifically for misclassified equipment changes. One case involved a company replacing a lyophilizer (freeze-dryer) without submitting a Prior Approval Supplement (PAS), even though the new unit had different pressure controls that affected drying time. The product was pulled from shelves. The lesson? Don’t guess. Classify carefully.

The Three Tiers of FDA Change Classification

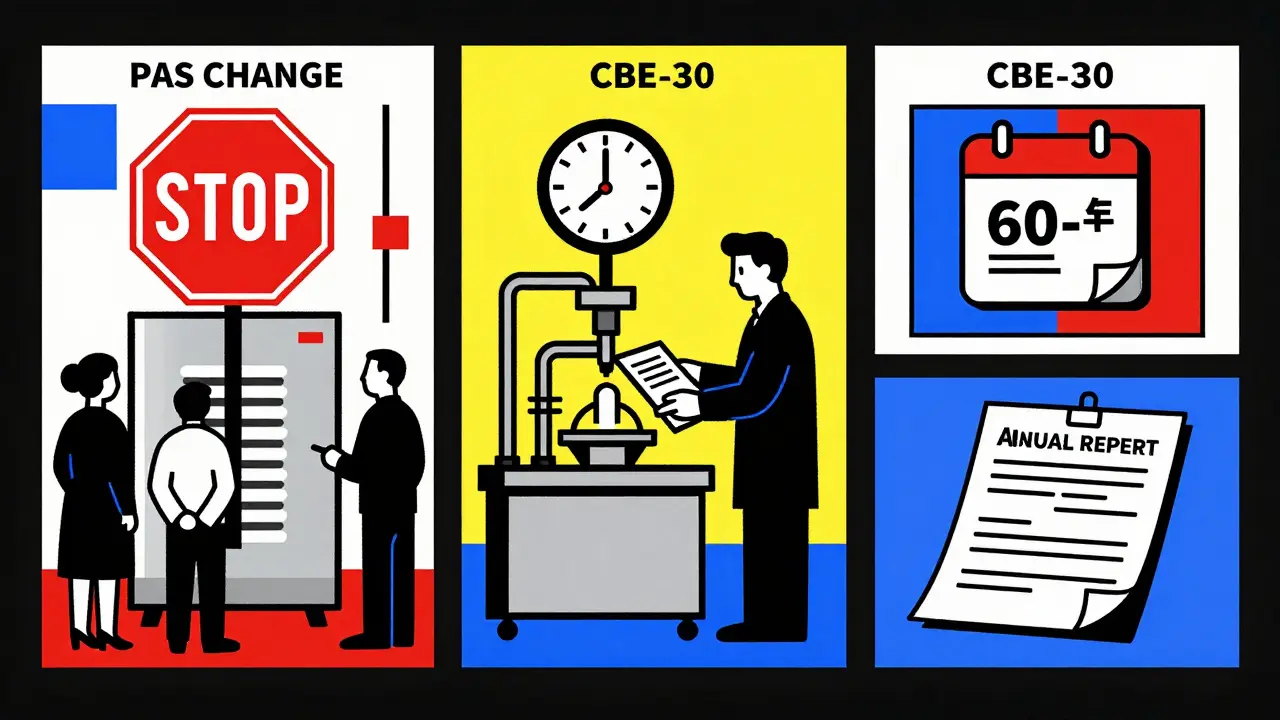

The FDA uses a three-tier system to manage manufacturing changes. Each tier has its own rules for notification, timing, and approval.- Prior Approval Supplement (PAS) - For major changes. These are changes with a high risk of affecting product quality. Examples include switching the synthetic route for an active ingredient, moving production to a new facility, or changing equipment that controls critical process parameters. You must get FDA approval before you make the change and ship the product. This can take 6 to 12 months.

- Changes Being Effected in 30 Days (CBE-30) - For moderate changes. These are changes that could affect quality but aren’t high-risk. Examples: replacing a tablet press with an identical model from the same vendor, changing a filter supplier, or updating software on a filling machine. You can make the change after submitting the supplement, but you must wait 30 days before shipping. If the FDA objects, they’ll tell you before the 30 days are up.

- Annual Report - For minor changes. These are low-risk, like moving a packaging line within the same building, changing the font on a label, or updating a non-critical validation document. You don’t need to notify the FDA ahead of time. Just document it and include it in your annual report, due within 60 days of your application’s anniversary date.

It’s not always clear which category a change belongs to. That’s why companies use risk assessments. The FDA recommends using ICH Q9 principles-like Failure Modes and Effects Analysis (FMEA)-to score potential impacts. A change that affects critical quality attributes (CQAs) like dissolution rate or particle size automatically pushes you into PAS territory.

How Other Regulators Compare

The U.S. isn’t alone. Europe, Canada, and global bodies have their own systems, and they don’t always match.| Regulator | Minor Change | Moderate Change | Major Change |

|---|---|---|---|

| FDA (U.S.) | Annual Report | CBE-30 (notify 30 days before) | PAS (approval before change) |

| EMA (Europe) | Type IA (notify within 12 months) | Type IB (approval before change) | Type II (full review before change) |

| Health Canada | Level III (annual notice) | Level II (notify and wait) | Level I (prior approval) |

| WHO Prequalification | Not defined | Comparability Protocol required | Comparability Protocol required |

The biggest difference? Timing. The FDA lets you make moderate changes 30 days after notice. EMA requires approval before you even start. Health Canada’s Level II is similar to CBE-30 but with no fixed clock. WHO requires detailed comparability data-stability tests, bioequivalence studies-for even small changes. If you’re making global products, you’re juggling four different rulebooks.

What Counts as an “Equivalent” Replacement?

One of the most common points of confusion is equipment replacement. Can you swap a mixer for another one? The FDA says yes-if it’s equivalent. But what does that mean?According to FDA’s 2022 guidance, “equivalent” means:

- Same principle of operation

- Same critical dimensions

- Same material of construction

- No change to critical process parameters (CPPs)

If you replace a stainless steel mixer with a ceramic one-even if it’s from the same brand-you might be changing how the product mixes. That’s not equivalent. That’s a PAS. A 2023 audit of 12 pharmaceutical companies found that 40% of equipment replacements were misclassified because teams focused on brand or model number, not process impact.

Pro tip: Document your reasoning. If you classify a change as CBE-30, you need to show evidence-validation data, process monitoring logs, batch comparisons-that proves no CQAs were affected. The FDA doesn’t accept “we’ve always done it this way.” They want data.

Real-World Challenges

The process isn’t just technical-it’s messy. A senior regulatory affairs specialist on Reddit shared a story: replacing a tablet press took 37 hours of meetings across QA, manufacturing, and validation teams. Why? Because the API’s particle size specs were vague. Was the change minor? Moderate? No one knew. They ended up submitting a PAS just to be safe. That cost $120,000 in delays.Small companies feel this hardest. A 2022 Deloitte survey found that only 63% of mid-sized manufacturers had formal change classification systems. Large companies like Pfizer use internal risk-scoring tools with 15+ criteria: impact on CQAs, process validation history, supplier reliability, even past inspection findings. They score each change out of 100. Anything above 70? PAS. Below 30? Annual report. In between? CBE-30.

Training is another hurdle. ASQ data shows regulatory specialists need an average of 18 months of hands-on experience to consistently classify changes correctly. Many companies now require certification in ICH Q9 risk management before letting staff handle change submissions.

What’s Changing in 2025?

The system is evolving. The FDA’s 2023 draft guidance on quality risk management pushes companies to use real-time data from sensors and automated monitoring systems to justify lower-risk classifications. Six major companies are already piloting this. Instead of submitting batch data after the fact, they’re using live process analytics to prove stability-cutting approval times by 30-40%.Europe’s EMA introduced “Type IB accelerated” pathways in January 2023. Certain equipment changes now get reviewed in 30 days instead of 60. It’s a step toward faster approvals without sacrificing safety.

And for advanced therapies-like gene therapies or CAR-T cell treatments-the rules are shifting fast. In 2022, 78% of manufacturing changes for these products required PAS submissions. That’s because the products are so sensitive. A tiny shift in temperature during cell culture can ruin a batch. Regulators are working on specialized frameworks, but for now, assume: if it’s complex, it’s major.

What You Need to Do

If you’re managing manufacturing changes, here’s your checklist:- Document every change-no matter how small. Even if it’s just a new label supplier, write it down.

- Use a risk assessment tool. Don’t rely on gut feeling. Use FMEA or a simple scoring matrix.

- Compare your change to FDA’s 2021 guidance on biologics. It includes a table of common changes and their recommended categories.

- If you’re unsure, ask the FDA. The 2021 guidance says: “Early consultation is encouraged.” You can request a pre-submission meeting. It costs time, but it saves you from a recall.

- Train your team. Make sure QA, manufacturing, and regulatory staff all speak the same language. Use real examples from past FDA warning letters.

- Track your submissions. Keep a log of every PAS, CBE-30, and annual report. You’ll need it for audits.

Manufacturing changes aren’t about slowing things down. They’re about making sure the medicine you produce today is the same medicine patients trusted yesterday-and will trust tomorrow.

What happens if I make a manufacturing change without submitting the right paperwork?

The FDA can issue a warning letter, seize your product, or order you to stop distribution. In fiscal year 2022, 22% of all FDA warning letters were for improper manufacturing changes. One company was forced to destroy $18 million worth of product after replacing a filter without a PAS. Even if the product is safe, the violation alone can trigger a recall.

Can I make a change and then notify the FDA later?

Only for minor changes (annual report) and moderate changes under CBE-30. For CBE-30, you submit the notice and wait 30 days before shipping. For major changes (PAS), you must wait for approval-no exceptions. Any change made without proper submission is a regulatory violation, regardless of intent.

How do I know if my equipment is “equivalent”?

The FDA defines equivalent equipment as having the same principle of operation, same critical dimensions, and same material of construction. You must also show that the change doesn’t affect critical process parameters (CPPs) or critical quality attributes (CQAs). If you’re replacing a pump, compare the flow rate, pressure, and shear force. If they’re within ±5%, and the material is the same, it’s likely equivalent. Document everything.

Do I need to resubmit if I change suppliers for a raw material?

It depends. If the new supplier provides the same specification and you’ve validated that the material performs identically in your process, it may qualify as a CBE-30. But if the material has different particle size, moisture content, or impurity profile, it’s likely a PAS. Always run comparative testing on at least three batches before deciding.

Are there tools to help classify changes?

Yes. The FDA’s 2021 final guidance for biologics includes a table with over 50 common changes and their recommended categories. Many companies also use ICH Q9-based risk assessment templates. Some ERP systems now have built-in change management modules that auto-classify changes based on your inputs. But no tool replaces human judgment-always validate the output with your QA team.

Manufacturing change control isn’t just about compliance. It’s about protecting patients, maintaining trust, and ensuring your product doesn’t become a liability. The rules are strict, but they’re designed to keep people safe. Follow them carefully.

Comments (15)

Kathryn Lenn

February 8, 2026 AT 10:01

So let me get this straight-we spend $200k on a new mixer, but if it's 'equivalent' we don't need FDA approval? Bro. The last time someone said 'it's the same' with a pump, the whole batch turned into glue. This isn't regulation-it's a tax on innovation disguised as safety.

Ashlyn Ellison

February 8, 2026 AT 20:18

I work in pharma QA. The real nightmare isn't the PAS-it's when your engineer says 'it's just a swap' and then the CQAs drift 8% on batch 4. You don't need a PhD to know that if the dissolution curve looks like a mountain range, you're in trouble. Document everything. Even if it's boring.

Tasha Lake

February 8, 2026 AT 20:31

Anyone else use the ICH Q9 risk matrix with weighted factors? I built one that scores supplier history, process variability, and CQA sensitivity. Got it down to a 10-minute form. Saved us 3 weeks on last quarter's CBE-30. Happy to share the template if anyone wants it.

Jacob den Hollander

February 10, 2026 AT 01:48

I just wanna say… thank you. Seriously. I’m new to this, and this post broke down what felt like a wall of jargon into something I can actually use. My team’s been winging it for months. I printed this out. I’m putting it on the wall. You just made my job 40% less terrifying.

John Watts

February 11, 2026 AT 09:35

This is why I love this industry. We’re not just making pills-we’re holding hands with patients who don’t even know we exist. Every time someone changes a filter, they’re thinking: 'Will this hurt someone?' And if they pause for even a second? That’s integrity. That’s care. Keep doing the hard thing.

Alex Ogle

February 12, 2026 AT 21:26

I’ve seen it happen. A company replaced a lyophilizer because ‘it was the same model.’ Turned out the new one had a 0.5 psi higher vacuum. Result? Product dried too fast. Cracked. Lost 800k in inventory. FDA came in. Shut them down for 4 months. The worst part? They had the data. Didn’t look at it. Just assumed. Don’t be that guy.

Frank Baumann

February 14, 2026 AT 01:07

I work for a small biotech. We had a change last year-switched from glass to plastic vials. Thought it was an annual report. Turned out the new plastic leached trace organics into the solution. We didn’t catch it until a patient had a reaction. We lost $2.3M. FDA didn’t care about our ‘small company’ status. You think this is bureaucracy? No. It’s the only thing standing between you and a lawsuit that ends your career.

Monica Warnick

February 14, 2026 AT 02:55

I’m not saying the FDA is wrong… but who exactly is reviewing these PAS submissions? Some guy in a cubicle who’s never seen a tablet press? I’ve seen approval letters with typos. One said ‘PAS for changing the color of the pill.’ Like… what? Are we regulating aesthetics now? I think this whole system is a giant Rube Goldberg machine built by people who hate progress.

Angie Datuin

February 14, 2026 AT 23:18

I’ve been in this field 12 years. I’ve seen changes that were classified wrong. I’ve seen changes that were never classified. The truth? Most people just want to get it done. But if you skip the paperwork, you’re not saving time-you’re gambling with someone’s life. And that’s not worth a coffee break.

Karianne Jackson

February 16, 2026 AT 03:08

I don’t get why we make this so complicated. Just make the change. If it breaks, fix it. People don’t die from a bad mixer. They die from not getting the medicine at all. Why not just let companies fix stuff and then report later? Why punish the good guys?

Brandon Osborne

February 16, 2026 AT 22:16

Let’s be real. This isn’t about safety. It’s about control. The FDA doesn’t trust manufacturers. They don’t trust scientists. They don’t trust engineers. They trust paperwork. And if you don’t have the right box checked? You’re a criminal. Meanwhile, the same people who wrote these rules are drinking champagne in their penthouses while a kid in Ohio waits 6 months for his life-saving drug. This system is broken.

MANI V

February 18, 2026 AT 11:41

In India, we change equipment daily. No PAS. No CBE-30. We test. If it works, we use it. No one dies. Why? Because we trust our people. Here, you need 17 signatures just to change a lightbulb. This isn’t safety. This is fear dressed up as law. You are not protecting patients. You are protecting your job.

Andrew Jackson

February 18, 2026 AT 20:37

I’ve reviewed 300+ FDA submissions. The ones that fail? Always the same. Companies think ‘equivalent’ means ‘same brand.’ It doesn’t. It means ‘same function under identical parameters.’ If you can’t prove that with data, you’re not a professional-you’re a liability. And if you’re cutting corners? You’re not just risking your company-you’re risking America’s trust in medicine.

glenn mendoza

February 19, 2026 AT 13:38

I want to thank you for taking the time to lay this out so clearly. This is the kind of guidance that makes a difference-not just in compliance, but in culture. When teams understand the 'why' behind the rules, they don’t resent them. They own them. That’s how you build a legacy of safety. Keep sharing this. It matters.

Tom Forwood

February 21, 2026 AT 10:40

I’m the guy who replaced the pump without telling anyone. I thought it was fine. It was the same model. Same vendor. But the flow rate was off by 3%. We didn’t catch it until the stability study. Now I’m on mandatory training. I’m not mad. I’m just… really, really sorry. Don’t be me.